复合材料制备及评价

本课题组长期从事金属层状复合材料、纤维金属层板的(Fiber Metal Laminates,FMLs)以及纳米改性聚合物基复合材料的制备、成形及性能评价技术研究。

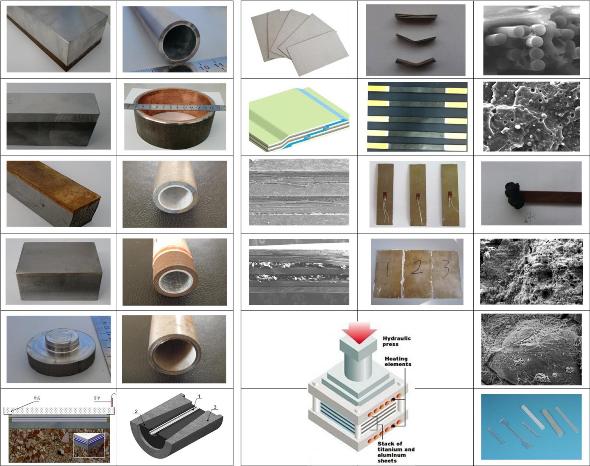

在金属层状复合材料的制备方面:采用爆炸复合、热压复合、超塑性扩散焊等先进技术及工艺制备了铝/钢双金属复合管、铝/铜双金属复合管、铜/钢双金属复合管、碳钢/不锈钢双金属复合管;铝/钢双金属复合板、钛/钢双金属复合板、铝/铜双金属复合板、钛/铝多层复合板(最多为11层)以及波纹夹芯复合板。采用多种微观表征手段对金属层状复合材料的界面形貌、元素分布、物相组成等进行了系统分析;另外对界面剪切强度、界面结合强度以及复合材料强度进行了系统的测试、分析。

在Glare层板(玻璃纤维-铝合金层板)制备及成形方面:已开展不同结构Glare层板热压制备技术研究及其专用真空热压装备研发;已开展以新型铝锂合金为基板的新型Glare层板研制工作,包括铝锂合金薄板的轧制、表面处理、热处理变形控制以及热压工艺优化研究;Glare层板在不同环境温度下的常规力学性能、韧性性能以及疲劳特性的测试分析技术研究;Glare复杂构件的成形技术研究,包括复杂构件的塑性成形技术以及Glare管材的内高压成形制备技术等。

在最新一代TiGr层板(碳纤维/石墨纤维-钛合金层板)的制备方面:研究了钛及钛合金的表面处理对层间粘接性能的影响;研究具有不同铺层方式(单向,正交,±45°)、不同结构(2/1,3/2,5/4)层板的力学性能、抗疲劳性能以及耐候性。

在纳米改性聚合物基复合材料的制备方面:研究纳米颗粒的改性机制及作用,界面优化设计,界面相容性及纳米颗粒在聚合物中的分散机制及关键技术,建立纳米添加剂与宏观力学性能的联系,发展具有优越的机械性能的先进热塑性复合材料,同时具有抗菌、抗静电、阻燃的功能特性;对纳米改性热塑性材料及其注塑成型工艺进行计算机仿真、优化及实验研究,确定最佳注塑成型工艺。

(1) 相关科研项目

[1] 高速列车蒙皮结构用超混杂复合材料关键制造技术及应用性能研究(BE2018125),江苏省重点研发项目2018-2022;

[2] 材料基因工程关键技术与支撑平台重点专项-先进高分子基复合材料高通量制备研发及其在新一代飞机上的示范应用,国家重点研发计划,2017-2021;

[3] 高铁制动系统用碳纤维增强聚合物复合材料制品研发及产业化,江苏省重大成果转化项目,2015-2017;

[4] Ti/Al 及Ti/Al3Ti 层状复合材料协同变形机制与界面组织演化研究,国家自然科学基金,项目编号:51475231,2015-2018;

[5] TC4/Cf/PEEK混杂层板中的TC4/PEEK界面微米凹坑结构强韧化机理研究,国家自然科学基金,2015-2017;

[6] 核电及交通用高性能铝合金复合箔热轧复合关键技术,引领计划科研项目,2012-2015;

[7] 界面组织对铝-钛双金属塑性成形特性的影响机制研究,高等学校博士学科点专项科研基金项目,项目编号:20123218120029,2013-2015;

[8] “六大人才高峰”资助项目:汽车用低散发无卤阻燃高抗冲聚丙烯专用料的研制

[9] 镇江市科技攻关计划项目:高性能聚丙烯用以APP为基无卤阻燃剂的制备及产业化

[10] 江苏省发改委计划项目,同时也是江苏省教育厅计划项目: 抗菌ZnO/热塑性复合材料产业化关键技术研究

[11] 2006年度江苏省高校科研成果产业推进工程项目:纳米氧化锌/热塑性抗菌复合材料的产业化关键技术

[12] 江苏省普通高校高新技术重点项目: 纳米高强高韧聚烯烃汽车专用料。

[13] 航空航天用Ti/PEEK/Cf混杂层板的关键技术研究,NS2012056,2012年度南京航空航天大学基本科研业务费专项科研项目,2012-201。

(2) 相关专利

[1] 靳凯,陶杰,王浩,王建华,陈虞杰,袁其炜,一种高通量制备微键脱粘实验试样的装置及方法,专利号: ZL 201810009504.8 ;

[2] 陶杰;林炎炎;李华冠;钱德洪;王永红,纤维金属超混杂T形加筋结构的一体化成型模具及方法,申请号: CN 201910862798.3 ;

[3] 陶杰,李华冠,刘成,李华冠,林炎炎,陆一, 陈虞杰,华小歌,一种航空用新型混杂复合材料铆接方法及装置,专利号: ZL 201710864649.1 ;

[4] 陶杰; 王浩; 靳凯; 罗昊; 陶杨洋; 袁其炜; 陈虞杰,高通量计算研发新型高分子树脂基体的方法,申请号: CN201910047697.0 ;

[5] 陶杰; 靳凯; 王浩; 王建华; 袁其炜; 陈虞杰, 高通量表征单根纤维与树脂微观界面性能的装置及方法,申请号: CN201810171533.4 ;

[6] 陶杰; 靳凯; 王浩; 陶杨洋; 袁其炜; 陈虞杰,高通量测试纤维与树脂微观界面性能的制冷装置及方法,申请号: CN201910020138.0 ;

[7] 潘蕾,马文亮,王一凡,吕飞云,陶杰,郭训忠,一种复合层板制件的制备方法,专利号: ZL 201610035556.3 ;

[8] 潘蕾,陶杰,郭训忠,吕飞云,王一凡,具有整体式金属包覆层的复合材料压气机风扇叶片,专利号: ZL 201611224847.3 ;

[9] 潘蕾,胡玉冰,陶杰,戴琦玮,蔡雷,柏继华,朱建平,碳纤维增强聚酰亚胺树脂复合材料的制备方法,专利号:ZL 201410426652.1;

[10] 陶杰,李华冠,胡玉冰,郭训忠,Glare构件的制备成形方法,专利号:ZL 201410056071.3;

[11] 陶杰,胡玉冰,李华冠,郭训忠,玻璃纤维-铝合金复合管气压胀形制备方法及装置,专利号:ZL 201410048728.1;

[12] 陶杰,胡玉冰,李华冠,潘蕾,蔡雷,朱建平,碳纤维排布装置,专利号:ZL 201420063057.1;

[13] 潘蕾,陶杰,汪涛,蒋建辉,徐凤娟,杨栋栋,一种轻质抗冲击的泡沫金属夹芯板,专利号:ZL201220648704.6;

[14] 潘蕾,陶杰,汪涛,蒋建辉,徐凤娟,杨栋栋,一种轻质耐高温碳纤维金属混杂层板,专利号:ZL201220648916.4.;

[15] 潘蕾,陶杰,汪涛,蒋建辉,徐凤娟,杨栋栋,一种轻质耐高温碳纤维金属混杂层板,申请号:201210503117.2 。

(3) 相关论文

[1] Yanyan Lin, Huaguan Li, Qilitai Wang, Zhibing Gong, Jie Tao. Effect of plasma surface treatment of aluminum alloy sheet on the propertiesof Al/Gf/PP laminates. Applied Surface Science. 2020(507):145062.

[2] Hao Wang, Kai Jin, Jie Tao*. Effect of fiber surface functionalization on shear behavior at carbon fiber/epoxy interface through molecular dynamics analysis. Composites Part A: Applied Science and Manufacturing;126, 2019, 105611.

[3] Kai Jin, Hao Wang, Jie Tao*. Interface strengthening mechanisms of Ti/CFRP fiber metal laminate after adding MWCNTs to resin matrix. Composites Part B: Engineering; 171, 2019, 254-263.

[4] Kai Jin, Hao Wang, Jie Tao*. Mechanical analysis and progressive failure prediction for fibre metal laminates using a 3D constitutive model. Composites Part A: Applied Science and Manufacturing;124,2019,105490.

[5]Lei Pan,Fei Wang,Xiaofei Pang,Lei Zhang,Jianxiong Hao. Superhydrophobicity and anti-icing of CF/PEEK composite surface with hierarchy structure[J]. Journal of Materials Science,2019,54(24).

[6]Lei Pan,Yunfei Lv,Roy Nipon,Yifan Wang,Lixiang Duan,Jingling Hu,Wenye Ding,Wenliang Ma,Jie Tao,Yu Shi. Enhancement in Interfacial Adhesion of Ti/Polyetheretherketone by Electrophoretic Deposition of Graphene Oxide[J]. Polymer Composites,2019,40(S2).

[7]Lei Pan,Aiai Zhang,Zengmin Zheng,Lixiang Duan,Lei Zhang,Yu Shi,Jie Tao. Enhancing interfacial strength between AA5083 and cryogenic adhesive via anodic oxidation and silanization[J]. International Journal of Adhesion and Adhesives,2018,84.

[8] Yanyan Lin, Cheng Liu, Huaguan Li, Kai Jin, Jie Tao. Interlaminar failure behavior of GLARE laminates under double beam five-point-bending load. Composite Structures. 2018(201):79-85.

[9] Kai Jin, Yanyan Lin, Kai Cheng, Huaguan Li, Jie Tao. On the interplay behavior of fatigue crack growth and delamination of Ti/Cf/PMR polyimide hybrid laminates under overloading. Composites Part A. 2018(112):49-56.

[10]Lei Pan,Jingling Hu,Yunfei Lv,Wenliang Ma,Wenye Ding,Yifan Wang,Aiai Zhang,Fei Wang,Xiaofei Pang,Jie Tao. Modification of Ti-6Al-4 V plates with Schiff base complex and adhesive performance of Ti-6Al-4 V /PEEK[J]. Materials & Design,2018,144.

[11]Yunfei Lv. Effects of electrophoretically deposited graphene oxide on the surface of TA2 on the bonding strength of Ti/PEEK[C]. 国际复合材料委员会.第二十一届国际复合材料大会摘要集—专题一.国际复合材料委员会:中国复合材料学会,2017:1522-1525.

[12]Lei Pan,Zengmin Zheng,Aamir Ali,Yunfei Lv,Nipon Roy,Aiai Zhang,Yifan Wang,Minyu Fan,Jie Tao. Evaluation of the parameters of titanium surface micro-pits on the titanium-PEEK joint fracture toughness[J]. International Journal of Adhesion and Adhesives,2017,75..

[13]Lei Pan,Aamir Ali,Yifan Wang,Zengmin Zheng,Yunfei Lv. Characterization of effects of heat treated anodized film on the properties of hygrothermally aged AA5083-based fiber-metal laminates[J]. Composite Structures,2017,167.

[14]Aamir Ali,Lei Pan,Lixiang Duan,Zengmin Zheng,Bhuwan Sapkota. Characterization of seawater hygrothermal conditioning effects on the properties of titanium-based fiber-metal laminates for marine applications[J]. Composite Structures,2016,158.

[15] Li Huaguan, Hu Yubing, Liu Cheng, Zheng Xingwei, Liu Hongbing, and Tao Jie. The Effect of Thermal Fatigue on the Mechanical Properties of the Novel Fiber Metal Laminates based on Aluminum-lithium Alloy [J]. Composites Part A: Applied Science and Manufacturing, 2016, 84: 36-42.

[16] Pan Lei, Duan Lixiang, Zheng Zengmin, Hu Yubing, Aamir Ali, Bhuwan Sapkota, Tao Jie, Zhao Tong, and Du Zhengyang. Surface Characteristics and adhesive strength to polyetheretherketone of titanium electrografted with aryl diazonium salt [J]. Materials & Design, 2016, 95: 555-562.

[17] Du Dandan, Hu Yubing, Li Huaguan, Liu Cheng, and Tao Jie. Open-hole tensile progressive damage and failure prediction of carbon fiber-reinforced PEEK-titanium laminates [J]. Composites Part B: Engineering, 2016, 91: 65-74.

[18] Hu Yubing, Zhang Wei, Jiang Wei, Cao Liang, Shen Yizhou, Li Huaguan, Guan Zhongwei, Tao Jie and Xu Jiang. Effects of exposure time and intensity on the shot peen forming characteristics of Ti/CFRP laminates [J]. Composites Part A: Applied Science and Manufacturing, 2016, 91: 96-104.

[9] Li Huaguan, Hu Yubing, Fu Xuelong, Zheng Xingwei, Liu Hongbing and Tao Jie. Effect of adhesive quantity on failure behavior and mechanical properties of fiber metal laminates based on the aluminum-lithium alloy [J]. Composite Structures, 2016, 152: 687-692.

[20] Fu Xuelong, Hu Yubing, Tao Jie. Synthesis and tribological properties of copper-alumina nanocomposites prepared by coprecipitation technique [J]. Journal of Wuhan University of Technology-Mater. Sci. Ed., 2016, 31(5): 1123-1130.

[21] Xu Yiwei, Li Huaguan, Shen Yizhou, Liu Senyun, Wang Wentao and Tao Jie. Improvement of adhesion performance between aluminum alloy sheet and epoxy based on anodizing technique [J]. International Journal of Adhesion and Adhesives, 2016, 70: 74-80.

[22] Fu Xuelong, Tang Xiaobin, Hu Yubing, Li Huaguan and Tao Jie. Effect of different lay-ups on the microstructure, mechanical properties and neutron transmission of neutron shielding fibre metal laminates [J]. Journal of Nuclear Materials, 2016, 475: 227-236.

[23] Liu Cheng, Du Dandan, Li Huaguan, Hu Yubing, Xu Yiwei, Tian Jingming, Tao Gang and Tao Jie. Interlaminar failure behavior of GLARE laminates under short-beam three-point-bending load [J]. Composites Part B: Engineering, 2016, 97: 361-367.

[24] 徐飞, 潘蕾, 白云瑞等. 钛表面阳极氧化处理对TA2/聚醚醚酮(PEEK)粘结性能的影响[J]. 航空学报, 2013.11, 34: 1-9.

[25] 徐凤娟, 潘蕾, 杨栋栋等. 碳纤维钛合金超混杂复合层板残余应力研究[J]. 纤维复合材料, 2013, 06, (2): 3-8.

[26] 杨栋栋, 潘蕾, 徐凤娟等. Ti/APC-2纤维金属层板的制备及拉伸性能研究[J]. 纤维复合材料, 2013.03, 30(1): 8-11.

[27] Pan Lei, Wei Jiashun, Tao Jie. Study on Preparation and Mechanical Properties of Ti-PEEK-CfLaminates[J]. Advanced Materials Research, 2012, 570: P103-112.

[28] 魏佳顺, 潘蕾, 陶杰, 郭训忠. 表面处理对碳纤维润湿性及连续纤维增强PEEK复合材料拉伸性能的影响[J]. 纤维复合材料, 2010, 第4期: 36-40页.

[29] Tao Jie, Zhou Hui, Cui Yihua. Dielectric property of cyanate ester/nano-TiO2 particles or TiO2 whiskers encapsulated by polyaniline[J]. Key Engineering Materials, 2007, 334-335: 845-848.

[30] Tao Jie, Cui Yihua, Ji xuelai, Wo Dingzhu. Properties of biodegradable thermoplastic starch/ethyl cellulose composite[J]. Key Engineering Materials, 2007, 334-335: 345-348.

[31] Wang Yue-qin, Tao Jie, Wang Ling, He Ping-ting, Wang Tao. HA coating on titanium with nanotubular anodized TiO2 intermediate layer via electrochemical deposition[J]. Transactions of Nonferrous Metals Society of China. 2008, 18:631-635.

[32] Tao Jie, Wang Tao, Dong Xiang, Shan Xiaoqian. Mechanical Properties and Crystallization Behaviors of Nanostructured-ZnO/PET In-Situ Composites[J]. Journal of Nanoscience and Nanotechnology, 2006, 6(12): 3939-3942.

[33] 倪晓燕, 陶杰, 钱惠慧. 玻璃纤维增强聚丙烯制品翘曲变形的研究[J]. 工程塑料应用, 2006, 34(10): 32-34.

[34] 耿妍, 陶杰, 崔益华等. 聚磷酸铵微胶囊化的工艺研究[J]. 玻璃钢/复合材料. 2006,(3): 39-41.

江苏省南京市将军路29号南京航空航天大学将军路校区 邮编:211100

taojie@nuaa.edu.cn