材料塑性加工与装备

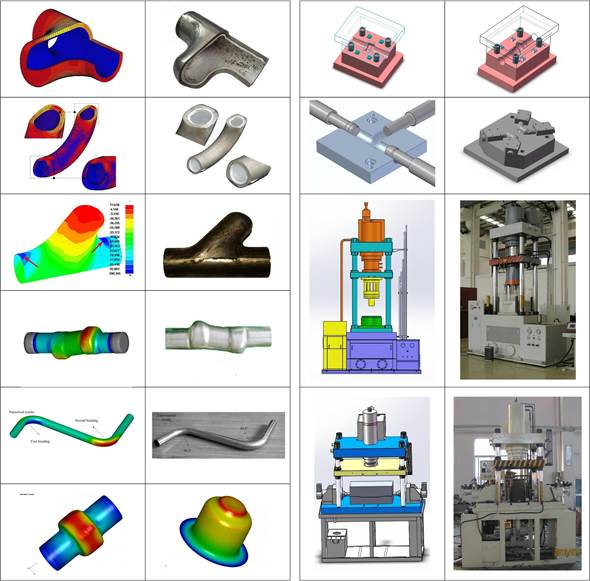

本研究小组长期从事金属塑性成形机理及关键技术、工艺及模具结构优化、智能化液压成形装备的系统研发工作。

在先进塑性成形机理及关键技术方面:对空心构件的液压、气压胀形以及精密弯曲成形机理进行了系统的研究;对双金属复合材料在大塑性变形过程中的内外层材料协同变形机制、界面分层机制及关键控制技术进行了率先探索。

在工艺及模具结构优化方面:采用有限元仿真软件对多种空心件的胀形、弯曲成形关键工艺参数进行了系统研究,同时对模具型腔以及冲头的结构形式进行优化分析,建立了规范、准确的多工步仿真分析程序。

在智能化数控液压成形装备研发方面:自主设计了管材自由胀形设备、管材内高压成形设备以及充液成形设备,设备功能完备,满足了管材成形性能参数精确获取、复杂管件成形以及复杂钣金件成形的需求,可以较好地代替同类进口设备。

目前,采用上述关键技术及装备,已经成功制造航空航天、核电、石化等领域所需的多通管件、弯头、弯管、汽车用空心结构件、双金属空心结构件;零件涉及到的材质包括铝合金、钛合金、不锈钢以及双金属等。另外,本课题组还进行了有关超薄精密不锈钢、航空航天用钛合金薄板以及新型铝锂合金的精密轧制研究工作。

(1) 相关科研项目

[1] 中央军委装备发展部装备预研基金重点项目,镍基高温合金复杂曲面构件精密成形技术,在研,主持;

[2] 国家自然科学基金国际合作交流项目,Ti/Al金属层状复合材料增量塑性成形机理与缺陷调控研究,在研,主持;项目编号:1006-GKA17097;

[3] 航空科学基金项目,铝锂合金GLARE叠层材料构件成形机理及缺陷调控研究,项目编号:1006-HAC16009;

[4] 江苏省基础研究计划(自然科学基金)面上研究项目, Ti/Al层板塑性变形与后续热压界面相调控机制研究,项目编号:1006-PAC15003;

[5] 国家自然科学基金面上项目, Ti/Al及Ti/Al3Ti层状复合材料协同变形机制与界面组织演化研究,项目编号:1006-GAA1502501;

[6] 企事业单位委托项目,第三代核电反应堆用控制棒驱动机构部件的关键制造技术研发,在研,主持;项目编号:1006-KFA18320;

[7] 企事业单位委托项目,金属板材成形性能应变网络及设备关键技术研发,项目编号:1006-KFA16328;

[8] 江苏省重大成果转化项目,进口替代航空航天紧固件用高温合金棒丝材研发及产业化,在研,参与;项目编号:1006-KFA19213-01;

[9] 江苏省重大科技成果转化项目:三代核电蒸汽发生器用安全止振组件成形技术研发与产业化,项目编号:BA2015163;

[10] 国家自然科学基金项目:界面组织对铝-316L不锈钢双金属塑性成形特性的影响机理研究,项目编号:51205196;

[3] 工业和信息化部船舶预研项目:新型液化天然气液货围护系统;

[11] 教育部博士点基金项目:界面组织对铝-钛双金属塑性成形特性的影响机制研究,项目编号:20123218120029;

[12] 中国博士后科学基金面上项目:聚变堆用CLAM钢/纯铝双金属复合管塑形变形机理研究,项目编号:2013M531347;

[13] 江苏省重大科技成果转化项目:基于LBB准则的AP系列核电站用无缝弯管关键成形技术研发与产业化,项目编号:BA2012124;

[14] 江苏省重大科技成果转化项目:航空航天及电子信息用钛合金与不锈钢精密薄板成型技术研发与产业化,项目编号:BA2010138;

[15] 江苏省重大科技成果转化项目:核电用不锈钢和钛合金管配件冷挤压成型及产业化,项目编号:BA2006067;

[16] 江苏省科技支撑计划项目:重型汽车用铝合金变速箱壳体压铸成型关键技术研究,江苏省科技支撑计划项目,项目编号:BE 2011049

[17] 江苏省科技支撑计划项目:环保、核电及船舶用高耐蚀哈氏合金管件的先进冷成形技术研究,项目编号:BE 2010163;

[18] 江苏省科技支撑计划项目:柔性太阳能电池及柔性显示产品用超薄不锈钢基材的精密成型研究,项目编号:BE 2009130;

[19] 中国科学院实验室开放项目:聚变实验堆用CLAM钢L形管件冷推弯成形关键技术研究,项目编号:20110628002;

[20] 国家商用飞机制造工程技术研究中心创新基金项目:新型铝锂合金的预变形及热处理对损伤容限和疲劳寿命的影响规律研究,项目编号:SAMC13-JS-15-032;

[21] 中航集团一飞院计划项目:6061航空铝合金超薄壁异形管路塑性成形及焊接关键技术;

[22] 镇江市领军人才创新创业项目:核级带直段弯管的内高压推弯成形关键技术研究;

[23] 江苏省博士生创新基金项目:316L/Al复合管冷成形及阻氚渗透涂层研究,项目编号:CX09B_077Z;

[24] 省部级科技鉴定项目:低活性马氏体钢管件的冷成形加工,2008年11月通过江苏省教育厅科技成果鉴定;

[25] 省部级科技鉴定项目:铝镁合金管件冷成形加工,2008年12月通过中国有色金属协会科技成果鉴定;

[26] 省部级科技鉴定项目:核电用无缝不锈钢管件的冷成形加工技术,2009年9月通过江苏省教育厅科技成果鉴定;

[27] 市级科技鉴定项目:柔性太阳能电池及柔性显示产品用超薄不锈钢基材的精密成型技术,2010年4月通过镇江市科技局的科技成果鉴定;

[28] 市级科技鉴定项目:航空航天用高品质钛合金薄板材及其精密成型技术,2010年4月通过镇江市科技局的科技成果鉴定;

[29] 市级科技鉴定项目:高温气冷堆用大转角带直段弯头冷成形技术,2011年3月通过镇江市科技局的科技成果鉴定。

(2) 相关著作

陶杰, 徐江, 李鸣, 刘红兵, 核能用合金管件的冷加工成型与防氚渗透涂层技术, 北京:原子能出版社, 2009, 10.

(3) 相关专利

[1] 郭训忠,熊昊,王辉,马燕楠,陶杰,徐勇.一种基于多足并联机器人的复杂构件三维自由弯曲成形方法,专利号: ZL 20171 0148448.1

[2] 郭训忠,马燕楠,王辉,陶杰,熊昊,靳凯.异形截面金属空心构件六轴自由弯曲成形装备及工艺解析方法,专利号: ZL 201710148463.6.

[3] 郭训忠,马燕楠,陶杰.一种金属管材3D自由弯曲成形方法及五轴自由弯曲设备,专利号: ZL201610977932.0

[4] 郭训忠,靳凯,马燕楠,陶杰,熊昊,王辉.一种提高金属三维自由弯曲成形极限的方法,专利号: ZL201710138362.0

[5] 郭训忠,马燕楠,陶杰.一种金属复杂构件3D自由弯曲成形工艺优化方法,专利号: ZL 201610981520.4.

[6] 郭训忠,王辉,谷岩波,陶杰.同时具有回转及非回转结构的钣金件增量渐进成形方法及装置,专利号: ZL 201610393769.3.

[7] 郭训忠,王辉,谷岩波,陶杰.一种航空轻合金板材差温渐进成形方法及装置,专利号: ZL 201610365265.0

[8] 郭训忠,陶杰,郭群.一种多级连续大变形零件的内高压成形方法及装置,专利号: ZL 201610142069.7

[9] 郭训忠,陶杰,金先玉,裴文娇.薄壁金属管推弯成形方法,专利号: ZL 201410132718.6

[10] 郭训忠,陶杰,范敏郁.具有Ti/TixAly/Ti多层结构的零件制备方法,专利号: ZL 201310722489.9

[11] 范敏郁,裴文娇,祁童百惠,郭训忠,陶杰,薄壁管管端密封装置及充液推弯成形方法,授权号:ZL 201310720343.0.

[12] 郭训忠,陶杰,金先玉,裴文娇,薄壁金属管推弯成形方法,授权号:ZL 201410132718.6.

[13] 陶杰,郭训忠,刘忠利,李百炼,具有局部压扁结构的空心零件成形方法,授权号:ZL 201410185536.5.

[14] 陶杰,王文涛,郭训忠,潘蕾,蔡雷,朱建平,具有波纹夹芯层结构复合板的制备方法,授权号:ZL 201410048716.9.

[15] 陶杰,郭训忠,热核聚变实验堆用防氚渗透无缝U形管路的制备方法[P],中国发明专利,授权号:ZL 200910264126.9.

[16]陶杰,郭训忠,李鸣,丁月霞,一种斜三通冷成形的制备方法[P],中国发明专利,申请号:200910029137.9;公开号:101450441.

[17] 陶杰,郭训忠,一种双金属T形三通管件的冷成形方法[P],中国发明专利,申请号:200910264544.8;公开号:101927277A.

[18] 陶杰,郭训忠,李鸣,丁月霞,用于斜三通脱模的顶出机构[P],中国实用新型专利,授权号:ZL 200920038550.7.

[19] 陶杰,郭训忠,李鸣,丁月霞,一种控制斜三通壁厚减薄率的装置[P],中国实用新型专利,授权号:ZL 200920038551.1.

(4) 相关论文

[1] Li T, Wang H, El-Aty A, Li J, Zhang Y, Wei W, Chen H, Cheng X, Tao J, Guo X*. Theoretical modelling and finite element simulation of AA6061 involute components based on 3D free bending process[J]. International Journal of Mechanical Sciences, 2020. Accepted

[2] Guo X, Cheng X, Xu Y, Tao J, El-Aty A, Liu H. Finite element modelling and experimental investigation of the impact of filling different materials in copper tubes during 3D free bending process[J]. Chinese Journal of Aeronautics, 2020, 33(2): 721-729.

[3] Guo Xunzhong, Jin Kai, Wang Hui, Pei Wenjiao, Ma Fuye, Tao Jie and Kim Naksoo. Numerical simulations and experiments on fabricating bend pipes by push bending with local induction-heating process [J]..

[4] Cheng X, Wang H, El-Aty A, Tao J, Wei W, Qin Y, Guo X*, Cross-section deformation behaviors of a thin-walled rectangular tube of continuous varying radii in the free bending technology[J]. Thin-Walled Structures, 2020, 150: 106670.

[5] Guo X, Yu Y, Tao J, Wang H, El-Aty A, Wang C, Luo X, Kim N. Maximum residual contact stress in spinning process of SS304/20 bimetallic pipe[J]. The International Journal of Advanced Manufacturing Technology, 2020, 106: 2971-2982.

[6] Guo Xunzhong, Jin Kai, Wang Hui, Pei Wenjiao, Ma Fuye, Tao Jie and Kim Naksoo. Numerical simulations and experiments on fabricating bend pipes by push bending with local induction-heating process [J]..

[7] Guo X, Wei W, Xu Y, EI-Aty A A, Liu H, Wang H, Luo X, Tao J. Wall thickness distribution of Cu-Al bimetallic tube based on free bending process[J]. International Journal of Mechanical Sciences, 2019, 150:12-19.

[8] Cheng X, Guo X*, Tao J, Xu Y, El-Aty A, Liu H. Investigation of the effect of relative thickness (t0/d0) on the formability of the AA6061 tubes during free bending process[J]. International Journal of Mechanical Sciences, 2019, 160: 103-113.

[9] Guo X, Wang C, Xu Y, Zhang S, El-Aty A. Incremental forming characteristics of hollow parts with grooves[J]. The International Journal of Advanced Manufacturing Technology, 2019, 102(1-4): 829-837

[10] Jin K , Wang J , Guo X . Experimental analysis of electro-assisted warm spin forming of commercial pure titanium components[J]. The International Journal of Advanced Manufacturing Technology, 2019.

[11] Guo X, Xu Y, Tao J, Zhang S. Advanced Cold Forming Technology For Metal Hollow Components [M]. Beijing: Science Press, 2019.

[12] Guo X, Xiong H, Li H, Xu Y, Ma Z, El-Aty A, Ma Y, Jin K. Forming characteristics of tube free-bending with small bending radii based on a new spherical connection[J]. International Journal of Machine Tools & Manufacture, 2018(133):72-84.

[13] Guo X, Ma Y, Chen W, Xiong H, Xu Y, EI-Aty A A, Jin K. Simulation and experimental research of the free bending process of a spatial tube[J]. Journal of Materials Processing Technology, 2018, 255:137-149.

[14] Guo X, Xiong H, Xu Y, Ma Y, El-Aty A, Tao J, Jin K. Free-bending process characteristics and forming process design of copper tubular components[J]. International Journal of Advanced Manufacturing Technology, 2018, 96(9-12):3585-3601.

[15] Guo X, Xiong H, Xu Y, El-Aty A, Zhao Y, Zhang S. U – R relationship prediction method for aluminum alloy circular tube free-bending process based on sensitivity analysis of material parameters[J]. The International Journal of Advanced Manufacturing Technology, 2018, 99(5-8):1967-1977.

[16] Guo X, Xiong H. Numerical simulation and experimental study on mechanism and characteristics of tube free-bending forming process[J]. Procedia Manufacturing, 2018(15):836-843.

[17] Wang H, Gu Y, Guo X, Wang H, Tao J, Xu Y. Microstructure and mechanical properties of 2060-T8 Al-Li alloy after warm incremental forming[J]. Journal of Mechanical Science and Technology, 2018, 32 (10): 4801-4812.

[18] Guo Q, Ma F, Guo X*, Tao J. Influence of mandrel on the forming quality of bending L-shaped hollow parts[J]. The International Journal of Advanced Manufacturing Technology, 2018, 95(9-12):4513-4522.

[19] Xiong H, Ma Y, Zhou S, He Y, Yang X, Jin K, Wang H, Luo X, Guo X*. Free bending forming technology of three dimensional complex axis hollow component[J]. Journal of Plasticity Engineering, 2018, 25(1): 100-110.

[20] Tao J, Xiong H, Wan B, Wei W, Cheng X, Wang L, Yu Y, Wang C, Guo X*. 3D Free-bending Forming Equipment and Key Technology[J]. Journal of Netshape Forming Engineering, 2018, 10(4).

[21] Xiong H, Wan B, Tao J, Wang L, Cheng X, Wei W, Guo X*. Three-dimensional Free-bending Technique and Numerical Simulation for Optimization of Deformation Zone Length[J]. Journal of Netshape Forming Engineering, 2018, 010(004):14-21.

[22] Guo X, Ma F, Guo Q, Luo X, Kim N, Jin K. A calculating method of tube constants of ductile fracture criteria in tube free bulging process based on MK theory[J]. International Journal of Mechanical Sciences, 2017, 128: 140-146.

[23] Guo X, Ma Y, Jin K, Wang H, Tao J, Fan M Y. Effect of stand-off distance on the microstructure and mechanical properties of Ni/Al/Ni laminates prepared by explosive bonding[J]. Journal of Materials Engineering and Performance, 2017, 26(9): 4235-4244.

[24] Guo X, Li B, Jin K, Wang H, Wang B F, Tao J. A simulation and experiment study on paraxial spinning of Ni-based superalloy tube[J]. The International Journal of Advanced Manufacturing Technology, 2017, 93(9-12): 4399-4407.

[25] Fan M, Yu W, Wang W, Guo X, Jin K, Miao R, Hou W, Kim N, Tao J. Microstructure and Mechanical Properties of Thin-Multilayer Ti/Al Laminates Prepared by One-Step Explosive Bonding[J]. Journal of Materials Engineering & Performance, 2017, 26(1):277-284.

[26] Jin K, Guo Q, Tao J, Guo X. A modified isotropic-kinematic hardending model to predict the defects in tube hydroforming process[J]. Journal of Materials Engineering and Performance, 2017, 26(11): 5188-5196.

[27] Qin L, Wang J, Wu Q, Guo X, Tao J. In-situ observation of crack initiation and propagation in Ti/Al composite laminates during tensile test[J]. Journal of Alloys and Compounds, 2017,712:69-75.

[28] Guo X, Wang L, Ling J, Ma F, Tao J, Xu Y, Jin K, Wang H. Simulation and experimental studies on hydrodynamic deep drawing of 2198 aluminum lithium alloy[J]. Rare Metal Materials and Engineering, 2017, 46(7): 1821-1826.

[29] Guo X, Fan M, Liu Z, Ma F, Wang L, Tao J. Explosive cladding and hot pressing of Ti/Al/Ti laminates[J]. Rare Metal Materials and Engineering, 2017, 46(5): 1192-1196.

[30] Ma Y, Xiong H, Wang H, Luo X, Jin K, Xu Y, Tao J, Guo X*. Simulation and Experimental Study on Three Dimensional Free Bending of Complex Space Elbow. Journal of Netshape Forming Engineering, 2017, 9(2):20-26.

[31] Fan M, Guo X, Cui S, Wu Q, Qin L, Tao J. One-Step Explosive Bonding Preparation of Titanium/Aluminum/Titanium Laminates with Three Layers[J]. Rare Metal Materials and Engineering, 2017, 46(3): 770-776.

[32] Guo Xunzhong, Jin Kai, Wang Hui, Pei Wenjiao, Ma Fuye, Tao Jie and Kim Naksoo. Numerical simulations and experiments on fabricating bend pipes by push bending with local induction-heating process [J]..

[33] Guo Xunzhong, Liu Zhongli, Wang Hui, Wang Liuan, Ma Fuye, Sun Xianjun and Tao Jie. Hydroforming simulation and experiment of clad T-shapes [J]. The International Journal of Advanced Manufacturing Technology, 2016, 83(1-4): 381-387.

[34] Sun Xianjun, Su Xuming, Tibbenham Patricia, Mao Jianghui and Tao Jie. The application of modified PVT data on the warpage prediction of injection molded part [J]. Journal of Polymer Research, 2016, 23(5): 1-10.

[35] Wang Wentao, Fan Minyu, Li Jinlong and Tao Jie. Interfacial microstructure evolution and shear strength of titanium sandwich structures fabricated by brazing [J]. Journal of Materials Engineering and Performance, 2016, 25(3): 774-780.

[36] Ma Fuye, Jin Kai, Wang Hui, Pei Wenjiao, Tang Xiaobin, Tao Jie and Guo Xunzhong. Flow stress analysis and hot bending of P11 alloy steel [J]. Journal of Materials Engineering and Performance, 2016, 25(9): 3725-3736.

[37] Guo Xunzhong, Wang Hui, Liu Zhongli, Wang Liuan, Ma Fuye and Tao Jie. Interface and performance of CLAM steel/aluminum clad tube prepared by explosive bonding method [J]. The International Journal of Advanced Manufacturing Technology, 2016, 82(1-4): 543-548.

[38] Sun Xianjun, Su Xuming, Mao Jianghui, Tibbenham Patricia and Tao Jie. The application of modified viscoplastic constitutive relationship on the warpage prediction of injection-molded part [J]. The International Journal of Advanced Manufacturing Technology, 2016: 1-10.

[39] Jin Kai, Guo Xunzhong, Tao Jie, Wang Hui, Kim Naksoo and Gu Yanbo. A model of one-surface cyclic plasticity with Lemaitre damage criterion for plastic instability prediction in the incremental forming process [J]. International Journal of Mechanical Sciences, 2016, 114: 88-97.

[40] Fan Minyu, Domblesky Joseph, Jin Kai, Qin Liang, Cui Shengqiang, Guo Xunzhong, Kim Naksoo and Tao Jie. Effect of original layer thicknesses on the interface bonding and mechanical properties of Ti-Al laminate composites [J]. Materials & Design, 2016, 99: 535-542.

[41] Guo Xunzhong, Tao Jie, Wang Wentao, et al. Effects of the inner mould material on the aluminium-316L stainless steel explosive clad pipe [J]. Materials and Design, 2013, 49: 116-122.

[42] 郭训忠, 陶杰, 张立伍,等. 爆炸焊接TA1/Al复合管的界面及性能研究[J]. 稀有金属材料与工程, 2012,41(1): 139-142.

[43] Xunzhong Guo, Jie Tao, Zheng Yuan. Effects of rigid mandrel and lubrication on the process of elbow parts by cold push-bending [J]. Advanced science letters, 2011, 4: 2618-2622.

[44] X.Z. Guo, J. Tao , H.B. Liu, et al. Hydroforming simulation and preparation of low activation martensitic steel Y-shapes. Nuclear Engineering and Design, 2011, 241: 2802-2806.

[45] SUN Xianjun, TAO Jie, GUO Xunzhong. Bonding properties of the interface in Fe/Al clad tube prepared by explosive welding [J]. Transactions of Nonferrous Metals Society of China, 2011,21:2175-2180.

[46] 郭训忠,陶杰,唐巧生,等. TA1-Al双金属复合管冷推弯有限元模拟及试验研究[J],中国有色金属学报,2012,22,4: 1053-1062.

[47] Xunzhong Guo, Jie Tao, Zheng Yuan. Hydroforming Simulation and Experiment on Al 5083 T-shapes [J]. Advanced materials research, 2010, 97-101:2668-2671.

[48] 郭训忠,陶杰,刘红兵,等. 聚变堆用难变形CLAM钢三通成形模拟及试验研究[J].原子能科学技术,2010, 44(10): 1217-1222.

[49] 白云瑞,陶杰,郭训忠,等. 铝合金板料的成形性能及数值模拟研究[J]. 锻压技术, 2013,38(3): 189-193.

[50] 郭训忠,陶杰,刘红兵,等. CLAM钢异径管冷成形数值模拟及试验研究[J]. 核科学与工程, 2011,31(2): 111-115.

[51] 郭训忠,陶杰,汪涛,唐巧生. 复杂形状钛管件内表面氧化铝涂层综合制备新工艺研究[J]. 中国机械工程, 2011,22(20):2498-2502.

[52] 孙显俊,陶杰,郭训忠,等. 爆炸法制备铁/ 铝双金属复合管的界面组织与结合强度[J]. 机械工程材料,2011,35(2): 35-42.

[53] 郭训忠,陶杰,刘红兵,等. 爆炸焊接316L不锈钢/Al复合管的界面及性能研究[J]. 南京航空航天大学学报,2010,42(5): 641-644.

[54] 郭训忠,陶杰,刘红兵,等. 聚变堆用CLAM钢管件冷推弯成形数值模拟及试验研究[J], 核科学与工程,2010, 30(2): 11-17.

[55] 郭训忠,陶杰,李鸣,等. 模具型面及冲头对三通管件成形的影响研究[J], 中国机械工程,2010,21(15):1875-1878.

[56] 孙显俊,陶杰,郭训忠,等. Fe/Al复合管液压胀形数值模拟及实验研究[J]. 锻压技术,2010,35(3): 66-70.

[57] 张立伍,陶杰,郭训忠,等. Ti/Al双金属三通管件冷成形及热处理工艺[J]. 金属热处理,2010,35 (8): 65-69.

[58] 裴文娇,郭训忠,王文涛,陶杰. 316L奥氏体不锈钢高温流变行为的研究[J]. 塑性工程学报.

(5) 项目获奖

[1] 2016年度江苏省科学技术一等奖—“核岛用高性能关键金属构件精密塑性成形技术及装备”;(第1完成单位)

[2] 2011年度高等学校科学研究优秀成果科技进步二等奖—“核级高性能无缝不锈钢管件冷成形关键技术与产业化”;(第1完成单位)

[3] 2012年度镇江市科技进步一等奖—“AP1000型核电站用带直段弯管及弯头成形技术开发与产业化”;(第1完成单位)

[4] 2009年度镇江市科技进步二等奖—“铝镁合金管件冷成型加工”;(第2完成单位)

[5] 2009年度南京航空航天大学科技进步二等奖—“低活性马氏体钢管件的冷成形加工”;(第1完成单位)

江苏省南京市将军路29号南京航空航天大学将军路校区 邮编:211100

taojie@nuaa.edu.cn